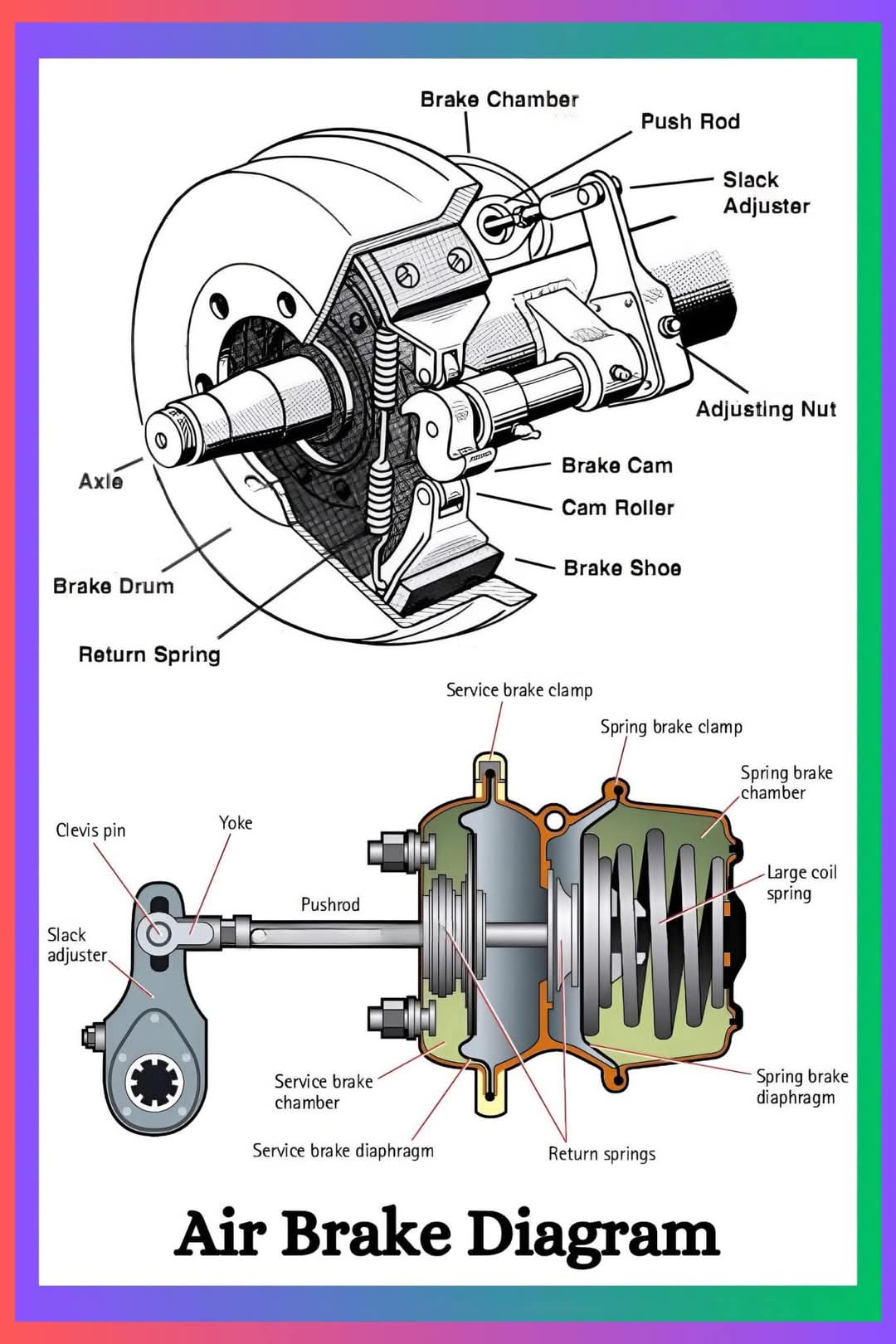

Air Braking System Explained: Parts, Working, Benefits, and Warning SignsThe air braking system is a reliable and efficient braking technology used in heavy vehicles such as trucks, buses, and trailers. Unlike hydraulic braking systems, air braking systems utilize compressed air to apply the brakes, providing a safer and more effective braking experience.Parts of an Air Braking SystemThe air braking system consists of several key components that work together to provide reliable braking performance. These components include:1. _Compressor_: The compressor is responsible for generating compressed air, which is then supplied to the system. The compressor is typically driven by the engine and is designed to provide a consistent flow of compressed air.2. _Reservoirs_: The reservoirs store compressed air for use in the braking system. The reservoirs are designed to provide a buffer against air pressure fluctuations and ensure a consistent supply of compressed air.3. _Brake Pedal/Foot Valve_: The brake pedal or foot valve controls the flow of compressed air to the brake chambers. When the driver presses the brake pedal, compressed air is directed to the brake chambers, applying the brakes.4. _Brake Chambers_: The brake chambers convert compressed air into mechanical force, which actuates the brakes. The brake chambers are designed to provide a consistent and reliable braking force.5. _Drum/Disc Brakes_: The drum or disc brakes provide the actual braking force to slow down the vehicle. The brakes are designed to work in conjunction with the air braking system to provide reliable and effective braking.6. _Control Valves_: The control valves manage air pressure and distribution in the system. The control valves ensure that the correct amount of compressed air is directed to the brake chambers.7. _Slack Adjusters_: The slack adjusters maintain proper clearance between the brake shoes and drums. The slack adjusters ensure that the brakes are properly adjusted and functioning correctly.8. _Air Dryer_: The air dryer removes moisture and contaminants from compressed air. The air dryer ensures that the compressed air is clean and dry, preventing damage to the braking system.9. _Governor_: The governor controls the compressor to maintain optimal air pressure. The governor ensures that the compressor operates within a safe and efficient range.Working of Air Braking System The air braking system operates by using compressed air to apply the brakes. When the driver presses the brake pedal, compressed air is directed from the reservoirs to the brake chambers. This air pressure pushes a diaphragm inside the chambers, converting pneumatic force into mechanical force, which activates the drum or disc brakes to slow or stop the vehicle.Releasing the pedal exhausts the air, disengaging the brakes. The air braking system is designed to provide a smooth and consistent braking experience, even in heavy-duty applications.Advantages of Air Braking System The air braking system offers several advantages over hydraulic braking systems. These advantages include:1. _High Reliability_: The air braking system is highly reliable and can withstand the rigors of heavy-duty applications.2. _Multiple Safety Features_: The air braking system features multiple safety features, such as dual-circuit systems, to ensure safe and reliable braking.3. _Effective Over Long Braking Periods_: The air braking system is effective over long braking periods without fluid boiling, providing a safe and reliable braking experience.4. _Easy to Integrate_: The air braking system is easy to integrate with trailers and additional systems, making it a versatile and convenient braking solution.Symptoms of Air Brake Issues there are several symptoms that can indicate air brake issues. These symptoms include:1. _Reduced Braking Efficiency_: If the air braking system is not functioning correctly, braking efficiency may be reduced, leading to longer stopping distances.2. _Hissing Sounds_: Hissing sounds can indicate air leaks in the system, which can lead to reduced braking efficiency and safety risks.3. _Excessive Pedal Travel_: Excessive pedal travel can indicate issues with the brake chambers or air pressure, leading to reduced braking efficiency.4. _Slow Brake Response_: A slow brake response can indicate issues with the air braking system, leading to safety risks and reduced braking efficiency.5. _Frequent Warning Signals_: Frequent warning signals for low air pressure can indicate issues with the compressor, air dryer, or other system components.Maintenance and RepairRegular maintenance and repair are crucial to ensure the optimal performance and safety of the air braking system. This includes:1. _Regular Inspections_: Regular inspections can help identify potential issues before they become major problems.2. _Proper Adjustment_: Proper adjustment of the brake chambers, slack adjusters, and other system components is essential to ensure optimal braking performance.3. _Air Pressure Checks_: Regular air pressure checks can help identify issues with the compressor, air dryer, or other system components.4. _Repair and Replacement_: Prompt repair and replacement of damaged or worn-out components can help prevent further damage and maintain optimal braking performance